Polyurea and polyurethane for waterproofing all surfaces

Polyurethane foam and polyurea are extremely useful materials for waterproofing, i.e., the process aimed at preventing water from penetrating the surfaces of any building structure, whether they are walls (including those against the ground), floors, solar roofs, terraces, bridges, viaducts, roads, pools, restoration and decoration works.

The advantages of waterproofing with polyurethane and polyurea are:

- Ease and speed of application: Applied by spraying, they harden in just a few seconds (3-5 sec).

- Ability to adapt to the expansions and contractions of the subsoil, without creating cracks.

- Homogeneous coating to the surface and possibility to reach all points without difficulty.

- Resistant to chemical and atmospheric agents.

- Unlimited tightness and durability.

- Reduced maintenance. Thanks to their durability and resistance they require less maintenance.

- Non-toxicity and respect for the environment.

- Resistance to wear and abrasion. A feature highly appreciated in the mechanical and industrial fields.

- Lightweight. Both materials are lightweight, making them ideal for applications where weight reduction is important.

- Adherence to various surfaces. Both polyurea and polyurethane have the ability to adhere to a wide range of surfaces, including metal, concrete, wood, glass and plastic.

- Fire Resistance: Some polyurethane foam formulations can be designed to have better fire resistance.

Application cases:

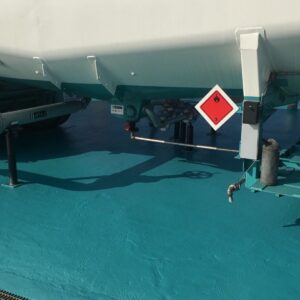

Waterproofing of swimming pools

The polyurea and polyurethane we produce are materials that can be applied by spray that is effective for waterproofing and insulation of swimming pools and other types of pools, whether they are newly built or already worn.

Over time, in fact, the coating loses impermeability, it can begin to peel off creating serious damage to the structure, so the treatment allows one to obtain a lasting result and several other advantages:

- Perfectly waterproof surface

- Seamless continuous waterproofing

- Fast curing times

- Resistance to chemical and atmospheric agents, impacts and abrasion

- Possibility of different colors

- Less maintenance

- Use of non-toxic and certified materials for food and drinking water

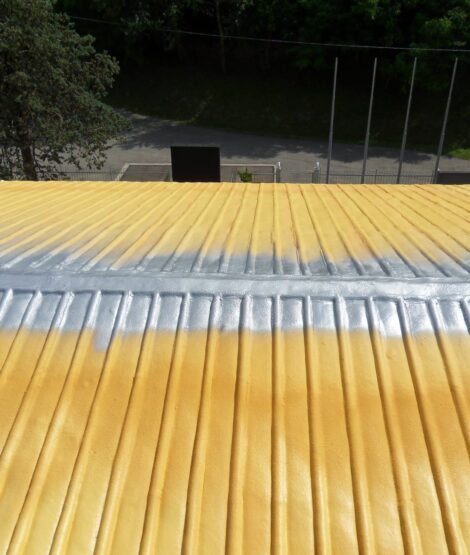

Waterproofing of roofs, floors and terraces

Polyurethane and polyurea make it possible to waterproof roofs, floors, and terraces, new or existing structures subject to infiltration. These products, applicable by spray, thanks to their specific characteristics, adhere perfectly to the surface and make possible a homogeneous protective layer, while also ensuring perfect thermal and acoustic insulation.

Polyurethane and polyurea offer waterproofing of roofs, sunscreens and terraces with a thin and light coating and are able to solve insurmountable problems with other systems.

Waterproofing of walls against the ground

Polyurethane and polyurea allow you to waterproof the walls against the ground and the foundations through the use of bi-mixer machines and spray application.

This way, it is possible to obtain an insulating surface that is smooth, homogeneous, elastic, resistant to water pressures and which protects buildings from possible infiltratio

Waterproofing of bridges, viaducts and roads

Spray-applied polyurethane and polyurea are ideal materials for waterproofing and protecting large public works such as bridges, viaducts, and roads. All of our waterproofing systems are driveable and available in non-slip versions.

Our materials are CE marked and meet all the characteristics required by the Public Administration for large public contracts.

Waterproofing of tanks and pipes for drinking water

Polyurethane and polyurea are ideal for waterproofing concrete surfaces intended for the containment of drinking water.

In particular, the FUTURE DRINKING WATER SYSTEM has been designed to apply the FUT 302 PW elastomeric coating, ideal for:

- Tanks

- Dams

- Canals

- Pipelines

FUT 302 PW has obtained the certification from the “Giordano Institute” for drinking water carried out according to the requirements of Ministerial Decree 6 April 2004 n. 174 – “Regulation concerning materials and objects that can be used in fixed installations for the collection, treatment, abstraction and distribution of water intended for human consumption“.

Given the incredible chemical resistance characteristics, FUT 302 PW can be used for waterproofing wastewater containment tanks, ponds, swimming pools and artificial lakes also intended for fish farming.

Restoration and decoration works

Making use of FUTURA EUROPE’s technology and materials, i.e., polyurethane foam and polyurea, means being able to intervene quickly, easily, and safely in the reconstruction of decorative elements and the reproduction of ornamental pieces of various kinds.

From a single original, or reproduced element, a mold is made from which various copies of the same element are made. The mold can be made directly on site, using spray technology. The opportunities for using this technology are many: it can be used for the reconstruction of a shelf as well as a capital or column.