Polyurethane and Polyurea for Various Applications

Polyurea is widely used in the industry to coat and protect a variety of surfaces. Its versatility makes it ideal for various industrial applications. We produce and distribute high-quality polyurethane and polyurea materials that are suitable for spray application in industries such as shipbuilding, petrochemicals, and for coating tanks and other special applications.

Primary Industrial Uses

- Industrial Flooring: Provides a durable and resilient surface for industrial floors.

- Pipeline and Tank Protection: Coatings for pipes, tanks, silos, and conduits, protecting them from corrosion and leaks.

Applications in Industrial Roofing

- Roofing and Sheds: Provides a waterproof and durable barrier.

- Waterproofing: Ideal for preventing water infiltration in industrial structures.

Advantages of Polyurea for the Marine Industry

- Corrosion Resistance: Effectively protects against salt corrosion and oxidation.

- Durability: Offers a robust barrier against scratches and impacts.

- Reduced Maintenance: Requires less maintenance compared to traditional coatings.

- Shipbuilding and petrochemicals: use of polyurethane and polyurea to protect structures and equipment in marine and petrochemical environments, ensuring strength and durability.

- Abrasion coatings: specialized coatings that offer superior protection against wear and abrasion in industrial and mechanical environments.

- Pipe-Line corrosion protection coatings: effective protection for pipes, preventing corrosion and extending their service life in environments exposed to chemicals and weather.

- Internal and external coatings of oil-bearing tanks: application of polyurea to seal and protect oil-bearing tanks, preventing leakage and environmental damage.

- Rust-proof encapsulation of metal parts and pipes: technique to coat and protect metal parts and pipes from rust and corrosion, ensuring increased longevity.

- Offshore applications and coatings, signal buoys and mooring liners: solutions for marine environments, including offshore buoy liners and structures that withstand extreme marine conditions.

- Military safety applications: use of polyurethane and polyurea in the military for protective coatings on vehicles and structures, offering resistance to adverse environmental conditions and impacts.

- Composite construction: use of polyurethane and polyurea in composite materials for building and engineering, improving structural strength and durability.

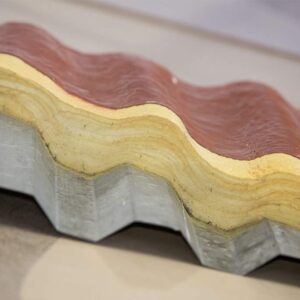

- Polyurethane foam for thermal insulation: use of polyurethane foam for effective thermal insulation in buildings, vehicles and industrial plants.

- Cold-rolled polyurea for fast coatings: Quick and low temperature application of polyurea, ideal for projects with time or environmental constraints.

Asbestos Encapsulation with Polyurethane and Polyurea

Asbestos encapsulation is a remediation technique that reduces the potential for fiber dispersion from compact asbestos materials. At FUTURA EUROPE, we have developed and patented various encapsulation systems using expanded polyurethane and polyurea applied by spraying. These materials act as thermal and acoustic insulators and are used in construction, cold storage industry, and transport of goods. Due to their excellent thermal insulation properties, low thermal conductivity, and suitable fire reaction, expanded polyurethane and polyurea ensure stable and durable adhesion and resist both high and low temperatures.

Specifically, FUTURA ELASTOMERS are formulated to be used as protective waterproofing coatings for roofing made of sheet metal, brick, metal, wood, and polyurethane foam, whether rough or smooth. They are also ideal for application on substrates such as membranes, concrete, bricks, and tiles.

Injections of hydrophilic materials

We design machinery and materials for injecting hydrophilic or hydrophobic substances into walls, soil, and cracks to block water infiltration and stabilize the subsoil.

Our application systems, including a bi-mixer spraying machine and a two-component polyurethane system, are tested to stop water ingress in any structure, perform sealings, and fill gaps to repel water, creating a unique and uniform barrier against infiltrations.