Polyurethane, the advanced technology for innovative applications in different sectors

Polyurethane is a material that has revolutionized the industry due to its versatility and the many innovative applications it offers. One field where polyurethane has proven to be extraordinarily effective is in the coating of polystyrene, a widely practiced method that results in a robust, flexible, lightweight, non-toxic product that is easy and quick to apply.

Polystyrene Coatings with Polyurethane and Polyurea Coating polystyrene with polyurethane offers several key advantages that make it a preferred choice in various contexts:

- Strength and Durability: Polyurethane imparts greater impact resistance and durability to polystyrene, making it suitable for a wide range of applications where robustness and durability are required.

- Flexibility and Lightness: Polyurethane-coated polystyrene is known for its light weight and flexibility. These characteristics make it ideal for applications where weight is a critical factor, such as in the automotive and aerospace industries.

- Safety and Non-Toxicity: The materials used in the process of coating polystyrene with polyurethane are non-toxic and safe for use. This safety is crucial, especially in applications involving food contact or use in health-sensitive environments.

- Ease of Application: The process of coating polystyrene with polyurethane is relatively simple and fast, which reduces production times and associated costs.

- Aesthetic Versatility: Polyurethane allows for customization of the appearance of polystyrene, offering a wide range of aesthetic options. This is particularly important in the furniture and design sectors.

We collaborate with American manufacturing companies, importing and distributing high-quality polyurethanes formulated for the most innovative applications. Indeed, coating polystyrene with polyurethane proves useful in various sectors:

- Scenography

- Visual communication

- Furniture

- Building

- Automotive

- Nautical industry

- Aerospace Industry

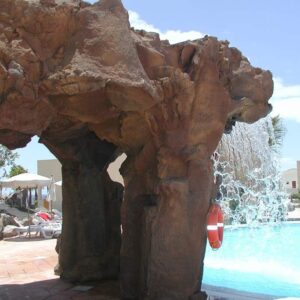

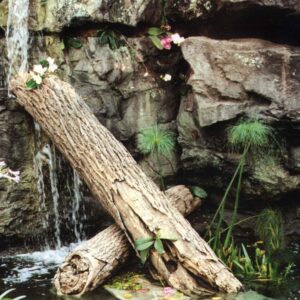

- Wellness centers, spas and swimming pools

- Mold making

- Packaging and wrapping

- Design and furniture

- Artificial rocks and trees

- Speakers

Types of Surfaces for Polyurethane or Polyurea Application

- Metal Surfaces: Expanded polyurethane and polyurea can be applied to metal surfaces such as steel, aluminum, and iron to protect them from corrosion and wear.

- Cement Surfaces: These materials are often used to coat cement surfaces like floors, walls, and roofs to provide insulation and protection against moisture and weather conditions.

- Wood: Expanded polyurethane can be used to insulate and protect wood from damage caused by moisture and weather conditions. Polyurea can be used to protect wood outdoors.

- Plastic: Both expanded polyurethane and polyurea can be applied to plastic surfaces to enhance their strength and durability.

- Thermal Insulation: Expanded polyurethane is commonly used for thermal insulation on walls, roofs, and floors in residential and commercial buildings.

- Waterproofing: Both materials are widely used for waterproofing surfaces such as pools, tanks, roofs, and terraces.

Benefits of Polyurethane and Polyurea for Protective Coatings

The use of polyurethane and polyurea as protective coatings is widely preferred in many applications due to the numerous advantages they offer. Here are some of the main reasons why polyurethane and polyurea are chosen as protective coating materials:

- Exceptional Resistance: Polyurethane and polyurea are known for their exceptional resistance to weather conditions, wear, corrosion, chemicals, and atmospheric agents. This resistance makes them ideal for protecting surfaces exposed to elements and corrosive substances.

- Surface Adaptability: These materials perfectly adapt to a wide range of surfaces, including metal, cement, wood, and others. This means they can be used to protect a variety of substrates without compromising their integrity.

- Continuous Coating: Polyurethane and polyurea coatings create a continuous and uniform protective layer without joints or weak points. This eliminates potential flaws or vulnerable areas, improving protection effectiveness.

- Quick Application: The ability to apply polyurethane and polyurea quickly is a significant advantage. Their rapid drying reduces downtime, allowing for faster resumption of normal activities.

- Lightweight and Durable: Despite being lightweight, polyurethane and polyurea coatings are known for their durability. This combination of lightness and strength makes them ideal for applications where weight is a critical factor.

- Aesthetic Customization: Polyurethane and polyurea coatings can be customized in terms of color and aesthetic appearance. This flexibility allows them to meet various design and style needs.

- Varied Applications: These coatings find application in a wide range of sectors, including industry and manufacturing, construction, automotive, shipbuilding, aerospace, electrical and electronic sectors, and many others. Their ability to protect against wear, corrosion, and environmental damage makes them a crucial choice for preserving and safeguarding surfaces and structures in numerous industrial and commercial contexts.