Machine for polyurethanes and polyurea spray FHI 3500

- Powerful and easy to use

- Maximum range and power

- Versatility for a variety of applications

- Long pipelines up to 100 meters

Powerful and easy to use, ideal for applying polyurea and polyurethane

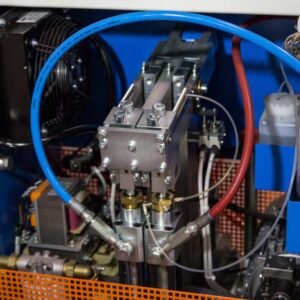

This spray machine for polyurea and polyurethanes, a bi-mixer proportional dosing machine with hydraulic propulsion, is designed for processes that require maximum flow rate and power.

Like all models in the FHI series, it guarantees both ease of use and flexibility. Designed for the spray application of polyurea, compact polyurethanes, or rigid & flexible polyurethane foams of any density, it allows you to maximize the opportunities of possible applications.

FHI 3500 polyurea spray machines allow you to:

- Ensure consistent performance over time due to high-quality mechanical processing elements

- Install piping up to 100 m in length

- Work on large production runs and square footage

- Spray expanded polyurethanes and polyureas at 1:1 ratio

- Make use of an automatic washing system part ISO

Advantages and fields of application of the FHI 3500 polyurethane and polyurea spray machine

The FHI 3500 polyurea and polyurethane spray machine stands out in the market due to its advanced features, which ensure efficiency, reliability, and precision in applications. With its robust and durable structure, this machine is designed to tackle the most challenging tasks in the industry and construction, delivering high performance under all usage conditions.

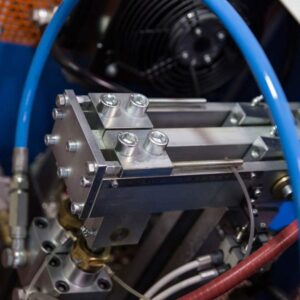

One of its key advantages is its high reliability, supported by a compact and straightforward design that simplifies operation and facilitates maintenance and repair activities. The structure, made entirely of treated steel, not only guarantees long-lasting durability but also serves as a reservoir for hydraulic oil, thereby maximizing operational efficiency.

The FHI 3500 machine is equipped with recirculation valves that reduce the crystallization of isocyanate and offer greater control over pressure balance. This feature, combined with the material pressure regulator and separate electric thermostats for ISO and POLY, allows for precise and customizable spray performance at any time, adapting to the various needs of different projects.

The FHI 3500 finds applications in various sectors, including construction, for waterproofing roofs, terraces, floors, retaining walls, and swimming pools. It is also ideal for thermal and acoustic insulation of buildings and for large-scale projects such as bridges, viaducts, and roads, offering anti-seismic and anti-corrosion protection solutions for tanks, viaducts, and structures in industrial environments.